Resiliency - Seismometer (page 3 of 3)

After landing, the drill is released from the capsule and lowered to the surface of the planet. Typical augers of this size on Earth use 1200 W electric motors. We expect to need no more than two minutes of drilling for the bit to be firmly planted in the ground. This will require approximately 40 W-h of energy.

To reduce artificial seismic readings due to potential movements of the lander from wind, the motor mechanism will be detached from the drill bit so that the lander is no longer rigidly attached to the seismometer. A loose cable with significant slack will connect the seismometer and the lander to power the device and read the measured seismic activity.

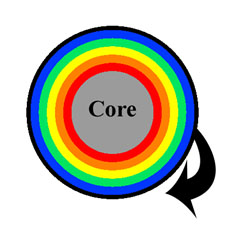

In order to prevent damage to the power and signal cabling due to the rotation required during placement, we propose a rotating-ring type connector, shown above. Signal wires are split into rings (represented by the colors) at the lower part of the rotating connector, which is attached to the seismometer. On the lander-side of the connector, conductive prongs extend down to make contact with each ring. As the lower connector rotates due to the motion of the drill bit, the prongs on the upper connector will continue to make contact with the correct wires. We believe this design will eliminate torsion on the cable while maintaining contact.